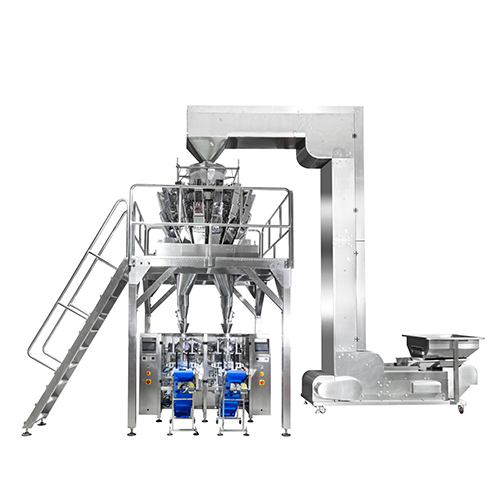

Multihead Weigher Packing Machine

Multihead Weigher Packing Machine

VIEW MORE

Different Dried Fruit Mixing Packing Machine

VIEW MORE

High Speed Snacks Packaging Production Line

VIEW MORE

Snacks with Sachet Filling Packing Machine

VIEW MORE

High Speed Twins Sugar Packing Machinery

VIEW MORE

Inclined Quad Seal Pouch Packing Machine

VIEW MORE

QQ Ball Snacks with Juice Mixing Packaging Machine

VIEW MORE

Gummy Candy Packaging Machine

VIEW MORE

Inclined Packing Machine for Fragile Food

VIEW MORE

Gusseted Bag with Degassing Valve Coffee Beans Packaging Machine

VIEW MORE

Fingers Biscuit Packaging Machine

Packaging Applications

Our packaging equipment features advanced technology, offering high precision, efficiency, and automation, ensuring stable and consistent packaging results.

Why Choose Multihead Weigher ?

Think of like having many small scales working together.A super-fast brain checks all their weights hundreds of times a second and picks just the right few scales whose weights add up perfectly to the bag's target weight,these scales dump together into the bag,and the process repeats in a fraction of a second.

- High Speed: weighing and calculation happen in parallel across many hoppers;cycles can be as fast as 100+ bags per minutes.

- High Accuracy: combination math minimizes error by selecting the best sum from many possibilities,compensating from minor variation in individual hopper fills.

- Versatility: handles a wide range of free-flowing granular products,such as chips,nuts,candy,frozen food,coffee beans,screws etc.

- Minimal Giveaway: precise weighing reduces product overfill and saving money.

- Gentle Handing: vibratory feeding is generally gentle on fragile products.

Frequently Asked Questions

-

What types of products are your packing machines suitable for?

-

Do your packing machines comply with international standards?

-

What does your after-sales service include?

-

Do you support customized packing machines?

-

Do you provide installation and training services?

Get A Quote Right Now

Prefer to slove all your questions together soon? We protect your privacy and respond within 24 hours.

-

EMAIL

-

-

WHATSAPP

-

ADDRESS

201#14 BUILDING,WANYANG INDUSTRIAL PARK, XIAOTANG INDUSTRIAL ROAD 82, SHISHAN TOWN, NANHAI DISTRICT, FOSHAN CITY, GUANGDONG PROVINCE, CHINA