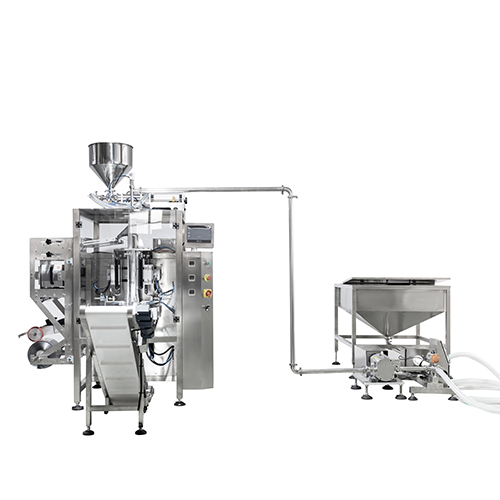

Liquid Packing Machine

Liquid Packing Machine

VIEW MORE

1kg Oil Filling Packing Machine

VIEW MORE

Four Side Sealing Paste Mix Liquid Packing Machine with TTO Printer

VIEW MORE

200ml Oil Sauce Packaging Machinery

VIEW MORE

Rotor Pump for Thick Paste Packing Machine

VIEW MORE

Peristaltic Pump Liquid Packing Machine

VIEW MORE

10ml Tomato Sauce Packaging Machinery

VIEW MORE

Four-side Sealing Liquid Packing Machine

Packaging Application

Liquid packaging machinerys are essential across numerous industries where accurace,hygienic,and efficient packaging of liquid is critical,inlcudes food & beverage,such as bottled water or drinks,juices & nectars,oil,sauce & condiments,soups & broths,alcoholic beverages,cosmetics & personal care,household & industrial chemicals etc.

Feature & Advantages

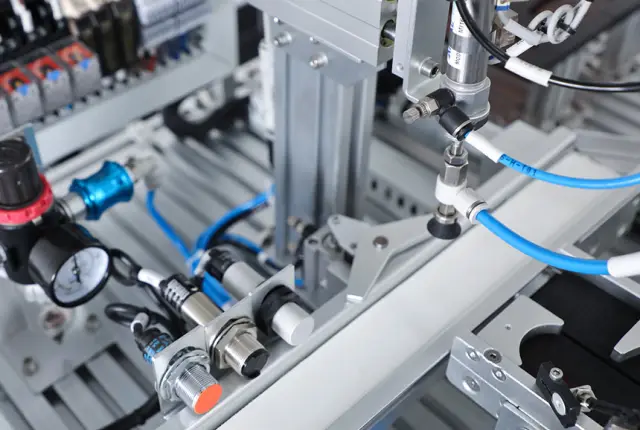

Advantage of pump-based-liquid filling is its unmatched versatility-it reliably and accurately handles the widest possible range of liquid types,viscosities,and product characteristics while offering excellent hygiene,precision,and control.This makes pump fillers indispensable for complex or demanding liquid packaging applications across deverse industries.The specific type of pump chosen ( peristaltic,piston,gear,rotor pump etc) further refines these advantages for particular product needs.

- Exceptional Versatility With Viscosity: pump fillers excel at filling products from very thin liquids to extremely thick,viscous material that would struggle in gravity fillers.

- High Precision & Accuracy: most pump types (piston,gear,peristaltic,rotor etc) are positive displacement,meaning they deliver a precise,repeatable volume per cycle or revolution.accuracy typically ranges from ±0.5% to ±1% of set volume.

- Easy of Volume Adjustment & Control: Mechanically with changing stroke length,rotor speed or pump rpm; Servo-driven via PLC control for quick changeovers.

Frequently Asked Questions

-

Could you please tell me which type pump can pack our product ?

-

How many types pump you have and what are they ?

-

How to clean it and is easy to clean ?

-

We have different weights to pack,do we need to change the pump ?

Get A Quote Right Now

Prefer to slove all your questions together soon? We protect your privacy and respond within 24 hours.

-

EMAIL

-

-

WHATSAPP

-

ADDRESS

201#14 BUILDING,WANYANG INDUSTRIAL PARK, XIAOTANG INDUSTRIAL ROAD 82, SHISHAN TOWN, NANHAI DISTRICT, FOSHAN CITY, GUANGDONG PROVINCE, CHINA